Hot Dip Galvanizing

Hot Dip Galvanizing in India

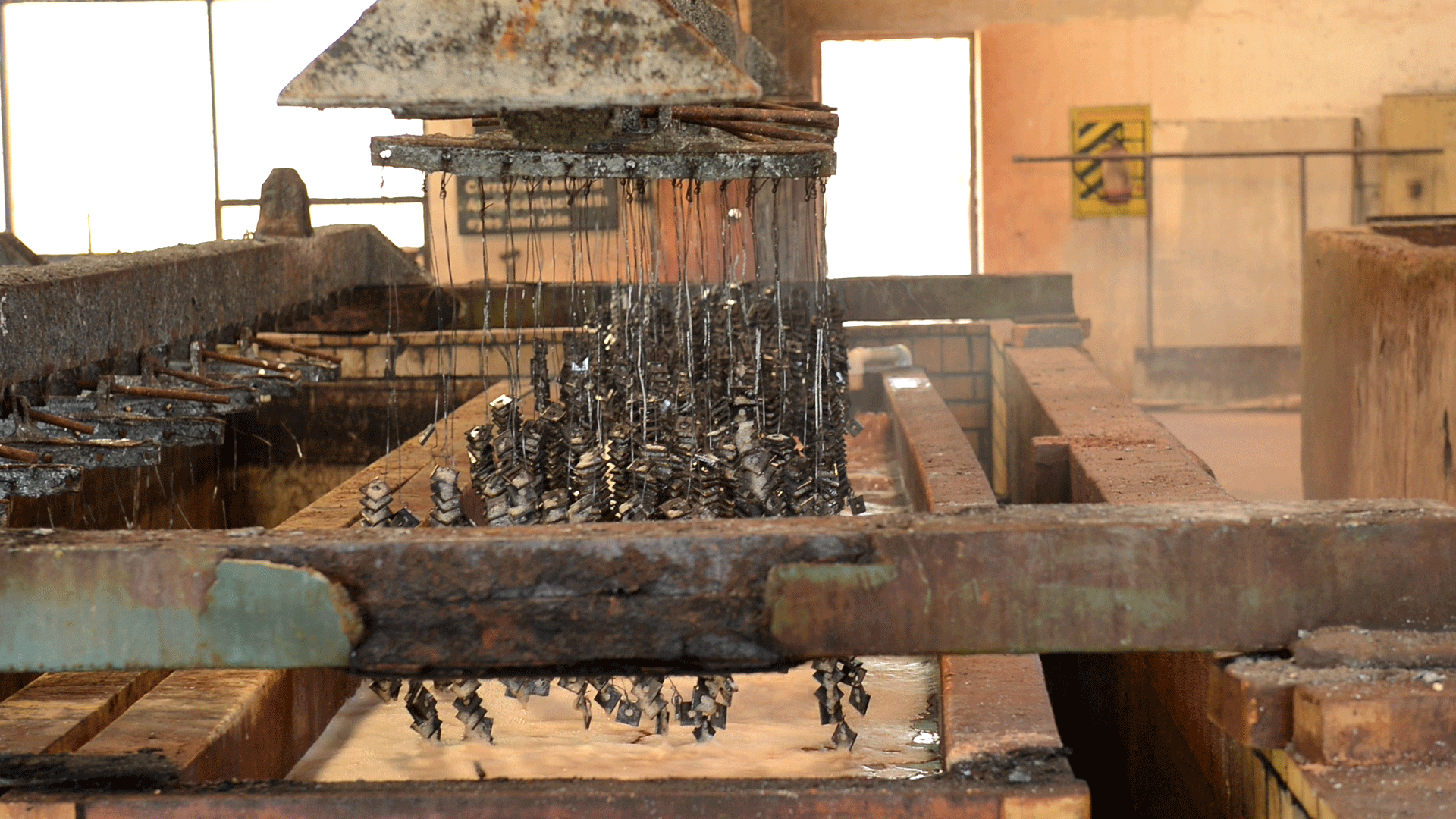

Steel is an abundant, efficient building material but often there is a need to protect it from the elements. Hot Dip Galvanizing is the best solution for corrosion protection because it provides long term solution to corrosion and can provide maintenance free protection for a long period of time. In today’s time, corrosion prevention is an essential factor in the economic utilization of steel.

Galvanizing Function

Our steel galvanizing process involves protecting the steel from the effects of corrosion by coating it with a thin layer of zinc that enhances its life. Our specialized hot-dip galvanizing unit that functions as per the specifications of BS, ASTM, JIS and DIN, delivers products that are maintenance-free and rustproof complete with flawless finishing. Henceforth we are one of renowned top 10 galvanizing companies in India operating predominantly over the years.

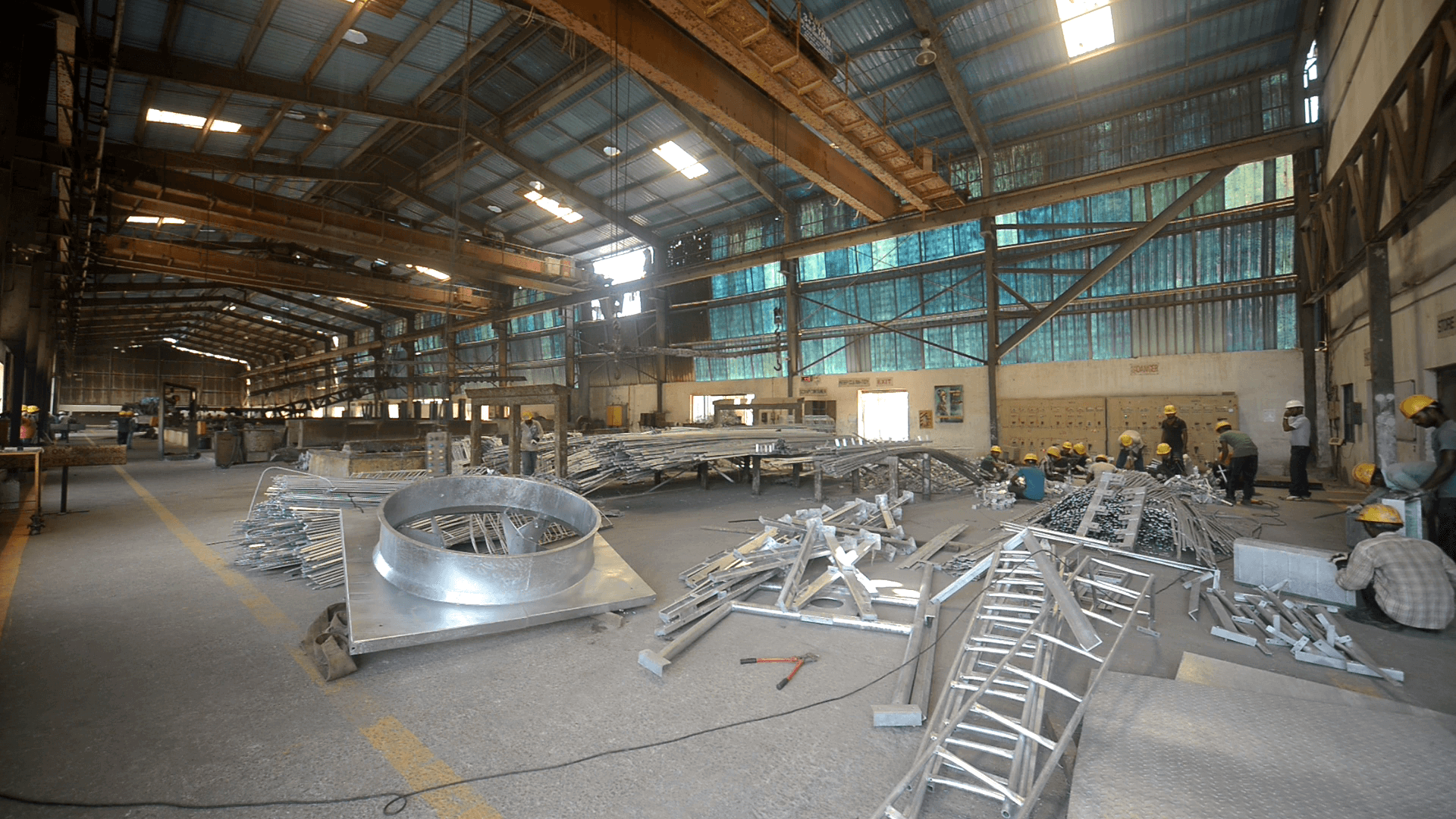

Galvanizing Unit

Our unit is equipped with advanced machinery such as high-tech poly-propylene tanks for pre-treatment processes, latest eco-friendly fume extraction systems and 4 EOT cranes with 3 +3 MT capacity that can produce 2,000 MT per month. Our commitment to quality and ethical business practices ensures that only branded raw materials are used to deliver quality products.

Highlights of the galvanizing unit are as follows:

- Galvanizing capacity of 3000 MT per month

- Galvanizing shed area of 2400 sq mtr

- Zinc kettle of size 10.5 Mtr Length

- Eco-friendly – latest fume extraction systems

- 15 Mtr Acid tanks for pretreatment process

- High-tech poly-propylene tanks for pretreatment process

- 4 EOT cranes – 3+3 MT capacity

- Galvanizing process as per IS 2629

- Testing facilities as per IS 2633

Various applications for Galvanization are

- Transmission Line Towers and parts

- Boiler accessories

- Galvanized Handrails

- Railway Electrification Structure

- Telecommunication towers and parts

- Switch yard structures

- Automotive parts

- Crash Barriers

- Windmill Structures

- Solar panel Structures

- Grating

- Fork Lift – 5 MT

- Mobile crane – 8MT,10MT,12 MT

- 60 MT weighbridge

- Power generators – 250 KVA and 140 KVA

- Solar Power Plant – 200 KWA

- Own transportation services